In the rolling process, the quality of the rolls is very important. Often due to the poor quality of the roll itself or improper operation, many rolling accidents occur, which bring losses to the steel mill. The following is a detailed analysis of the phenomena and causes of several rolling accidents that may occur.

What is the cause of mill rolls sticking?

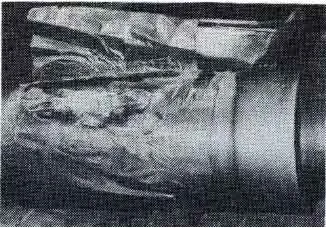

The sticking mill roll is caused by excessive local pressure, broken strip fragments and folded strip steel entering the rolling mill. Generally, the slightly sticky mill roll can continue to be used after manual grinding with grindstone. When the strip surface require is high, the mill roll must be changed.

During the cold rolling process, the surface of the roll bears great squeezing and intense wear. Steel jamming and over-burning during high-speed rolling will cause cracks on the roll surface. Therefore, cold-rolling work rolls should have extremely high and uniform hardness, a certain depth of hardened layer, and good wear resistance and crack resistance. The roll has good resistance to over burning and crack resistance is the main factor to extend the life of the roll.

What are the effects of insufficient mill rolls hardness on the rolling process?

The roll hardness is not enough, the elastic flattening is large during rolling, and the contact area between the roll and the strip surface is increased. To obtain the same thickness of the product, the rolling pressure must be increased, but the large rolling pressure is not good for the adjustment of the plate shape. The roughness of the roll is large, and the friction coefficient between the roll and the strip steel surface increases during rolling, which causes the friction force and the rolling pressure to increase.

How to use bending rolls to eliminate “both sides waves” and “middle waves”?

When waves appear on both sides of the strip during rolling, it means that the rolling pressure on both sides of the strip is too large. At this time, positive bending rolls are used to eliminate the waves on both sides. When there is an middle waves, it means that the original crown or thermal crown of the roll is too large. At this time, use a negative bending roll to eliminate.

How to prevent the skewing when the strip passes through the gap of the roll

First of all, before the strip passes through the gap of the roll, it must be minimize the clearance between upper and lower rollers, given a standard roll gap, it looks like the quality of the material, whether there are edge waves, and observe the strip running condition. In the rolling process, the deviation of the strip generally occurs during the strip passes through the gap of the roll or tail flicking. The main reasons for the skewing of the strip are as follows:

1)Due to the shape of the incoming material is not good, and there are serious edge waves, so that the strip edge control device cannot be accurately and timely adjusted effectively, causing the strip to deviate in the first pass. The measure to be taken is that control the rolling speed don’t be too high! Control the clearance between upper and lower roller, swing adjustment in time or stop in time.

2) Operational reasons: The unreasonable adjustment of the swing due to the the clearance between upper and lower roller causes the strip to run out of direction.

3) For electrical reasons, the coiler tension suddenly decreases or disappears during the rolling process, causing the strip to run off and break.

4) Due to the serious taper of the roll after the roll is ground, the clearance between upper and lower roller is inaccurate. During the rolling, the reduction and swing of the operation increase the difficulty. The lighter one will produce serious side waves and cause the plate shape defect, and the heavy one will cause deviation and broken strip.

5) The strip edge control device failure, the deviation device, the lamp tube or the pollution of the receiving device, etc., make the deviation device failure and cause the first deviation.

1) The roll body has a taper: the reduction cannot be corrected, and it is easy to cause a side wave, and the plate shape is difficult to control. The roll body taper is required to be less than 0.1mm.

2) Grinding is not round: the roll body has ellipticity. Vibration occurs during the rolling process, the rolling pressure fluctuates, and the strip thickness varies along the length direction.

3) Crown: The roll is required to be a flat roll in the process of the unit. If the roll has a crown,In the rolling process, it is easy to produce the middle wave and the second rib wave of the strip steel.

4) The surface roughness of the roll is too large. During the rolling process, the rolling pressure increases, the strip shape is difficult to control, and the surface quality of the strip is affected.

5) The roll body cracks, because the cracks have not been ditched and ground. The rolls were not inspected for flaw detection, and protruding rolling marks with crack shapes were generated on the surface of the strip during the rolling process.

No comments:

Post a Comment